Introduction

In this guide

In this guideOn this page

Skip the menu of subheadings on this page.This is a paper for discussion. This does not represent the views of the Committee and should not be cited.

Type A trichothecenes

6. T-2 and HT-2 are type A trichothecenes which are produced by a variety of Fusarium and other fungal species. Fusarium species grow and invade crops and produce T-2 and HT-2 under cool, moist conditions prior to harvest. They are found predominantly in cereal grains, and in particular oat grain, barley grain and wheat grain and products thereof (JECFA, 2016).

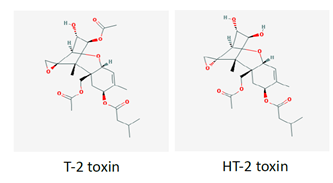

7. The chemical structures of T-2 and HT-2 are shown below in Figure 1.

Figure 1. Chemical structures of T-2 and HT-2 (PubChem, 2025).

Occurrence data

8. As part of this assessment, occurrence data on T-2 and HT-2 in food were acquired through a nationwide call for evidence (FSA, 2023). This call was issued by the FSA and FSS in July 2023 and officially closed in October 2023. However, the FSA and FSS continued to receive data up until February 2024. The data call focussed on cereals both pre- and post- cleaning/dehulling and finished products including, where possible, data that spans multiple years to reflect any annual variability of T-2 and HT-2 levels. The data received covered the UK harvest seasons from 2004 to 2023. Sampling data at retail level were also submitted for 2013 (n=60), 2014 (n=60) and 2024 (n=90).

9. The FSA and FSS received occurrence data on T-2 and HT-2, either as a sum or as individual mycotoxins. The level of detail provided by the respondents and the format varied, but the data included occurrence levels in processed and unprocessed cereal grains, cereal products and a small number of Ready to Eat (RTE) foods. The occurrence data submitted to the FSA and FSS were predominantly on unprocessed/raw materials, which were yet to undergo any cleaning. Occurrence data on grains submitted by industry as ‘already processed’ refers to grains that have been dehulled and cleaned, but remain as a commodity, that is they have not been incorporated in any RTE foods. Submitted data on RTE foods included biscuits, rusks and cookies, extruded cereal seed or root-based products, cereal bars, infant formula milk-based powder, oat porridge, muesli, mixed breakfast cereals, bread and rolls.

10. The data were collated, cleaned and assured within the FSA Exposure Assessment and Trade (EAT) team. The quality assurance (QA) methodology aligned with the main principles outlined in the aqua book (UK HM Treasury, 2015) and the guidelines in the government data quality framework (UK Governement Data Quality Hub, 2020) on data quality rules.

11. Prior to the data cleaning, a verification exercise was undertaken by the FSA to account for missing limit of quantification (LOQ) and/or limit of detection (LOD) values and sample type categorisation. For these amendments, assumptions were made based on the descriptors and values included by the submitters, such as the descriptors provided for commodity types based on the sample identification codes. The following criteria were applied to include data without compromising scientific integrity. Data were included when all of the following criteria were met:

a. Datapoints with reported LOQ > 0.

b. Datapoints where the FoodEx (EFSA, 2025) code could be defined.

c. Sample codes referring to products destined for human consumption (not feed).

12. For grains, only data on the sum of T-2 and HT-2, which were analytically determined in samples, were considered in the exposure assessment to allow for a direct comparison with the group HBGV (which is for the sum of both mycotoxins). For RTE products all reported values were considered, including individual T-2 or HT-2 occurrence data, due to the limited data available.

13. To estimate the median lower bound (LB) sum of T-2 and HT-2, values that were at or below the LOQ were assumed to be zero. To estimate the median upper bound (UB) occurrence levels, values that were at or below the LOQ were assumed to be at the LOQ; values above the LOQ were used as reported.

Seasonal variability

14. The presence of T-2 and HT-2 in crops is dependent on the weather at key growth stages such as flowering and can demonstrate large annual variability. While there are good agricultural practices deployed to manage the presence of mycotoxins in general, they have not proven to be effective for T-2 and HT-2, given the large dependence on climate/weather. Similarly, reliable rapid testing is not currently available. Currently, liquid chromatography mass spectrometry (LC-MS) and gas chromatography-mass spectrometry (GC-MS) are the primary techniques employed for testing T-2 and HT-2 contamination levels. However, recent assessments by industry see large variability between the methods developed, and performance characteristics such as limits of detection (LODs) and limits of quantification (LOQs) are often lacking (Safefood, 2024). This makes it difficult to reliably detect these toxins in samples. In addition, currently available test kits would not be ‘fit for purpose’ (Safefood, 2024) as rapid tests must be accurate, reproducible and provide the required sensitivity for regulatory compliance.

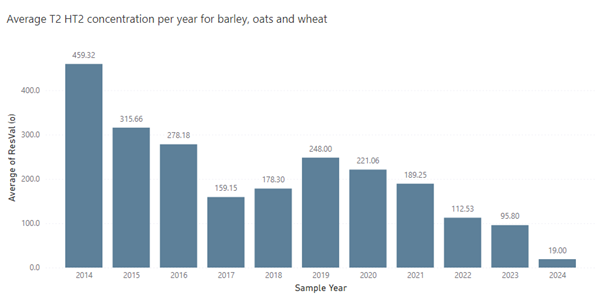

15. The data from the call for evidence covers the years 2004-2024, which spans a period either side of the EU recommendation from 2013 on the presence of T-2 and HT-2 toxin in cereals and cereal products (Commission Recommendation 2013/165/EU). Generally, the highest average levels of the sum of T2 and HT-2 from the data call were reported in the years 2008 to 2014, with lower levels being detected thereafter. The year 2014 is still recognised as a year with a particularly high prevalence of T-2 and HT-2, which could be attributed to seasonal variation, highlighting the importance of reviewing levels across a longer period of time.

16. Figure 2 provides time-trend analyses for the sum of T-2 and HT-2 in three cereal grains (barley, oats and wheat, both unprocessed grain and processed grain) from data submitted via the call for evidence. The average values in this graph are the averages of the median values per year. The year-on-year variability and seasonal trend provides an indication of the degree to which the presence of mycotoxins was impacted by climatic events at key stages of crop growth. To get a more representative, yet still retrospective analysis of current exposure patterns, only the last 10 years of residues data are included in this figure (2014- 2024); this excludes the data from before 2013, the year the initial food safety recommendation came into force. The Committee agreed that the temporal trend analysis of T-2 and HT-2 residues from 2004 to the present demonstrated an overall decline in the levels of these mycotoxins in unprocessed and processed cereal grains (oats, wheat and barley).

*ResVal(o) – concentration in µg/kg.

Figure 2. Average sum of T-2 and HT-2 concentration per year for ‘all grains’ (processed and unprocessed grains of barley, oats and wheat).

Reduction factors for unprocessed cereal grains

17. Unprocessed oat grains intended for human consumption comprise of an outer hull which is the part of the grain which is often most contaminated. However, this outer hull is removed during processing, and this so-called ‘de-hulling’ process therefore significantly reduces the level of contamination.

18. A literature search was conducted to identify any information on the reduction of T-2 and HT-2 mycotoxins in cereal grains during processing. A ‘reduction factor’, when used in exposure calculations, takes into account the expected decrease in T-2 and HT-2 levels in unprocessed cereal grains once they are processed, i.e. de-hulled. Applying reduction factors would therefore allow for a more accurate representation of consumer exposure to T-2 and HT-2 and result in a more realistic exposure assessment. Several reduction factors for the sum of T-2 and HT-2 for oat grains were identified in the scientific literature ranging from 66 to 100 % (Meyer et al., 2022; Schwake-Anduschus et al., 2010; EFSA, 2011a; Pettersson 2008). For this assessment, a reduction factor of 85 % from Meyer et al. (2022) was applied; this means that all T-2 and HT-2 occurrence values for unprocessed grains were reduced by 85 %.

19. The factor of 85 % was chosen as it was the most scientifically robust as well as from the most recently conducted study. Although the reduction factor of 85 % was specifically for large oat kernels, Meyer et al. (2023) noted that “milling oats are traded to contain less than 10 % of thin oats below 2 mm slotted hole sieve”; therefore, this reduction factor was considered to be of relevance for this exposure assessment.

20. As some cultivars of oat and barley are hulless, Polišenská et al. (2020) noted that “special attention should be paid to the risk of their contamination by Fusarium mycotoxins, as the rate of mycotoxin reduction during processing could be much lower than that for hulled cereals”. However, in the UK, hulless cultivars of oats are typically used for animal feed and not for human consumption.

21. No reduction factors were identified for maize or barley. The limited information available suggested that starting levels and incidence of T-2 and HT-2 in wheat and maize were very low and hence limited data were available on their fate or how their levels change during manufacturing of retail products (Scudamore, 2009). One publication by Pascale et al. (2011) calculated an overall reduction of T-2 and HT-2 toxins by 54 % following the processing of durum wheat. However, the samples used in this study were artificially inoculated with Fusarium, and as such the high concentrations of T-2 and HT-2 in this study are unlikely to reflect concentrations under natural conditions. Furthermore, the percentage reduction might not be linear and might be less at lower levels of expected contamination. Given the limited information it is therefore unclear whether, or to which percentage, processing reduces T-2 and HT-2 contamination in wheat, maize or barley under natural conditions, though it is expected to be negligible.